Calls to action around sustainability have increased in the past few decades, putting pressure on numerous stakeholders to adopt new ways of business. In particular focusing on sustainability in supply chains can help businesses achieve a significant positive impact, with 80% of global trade passing through supply chains.[1] Our last post discussed this trend in more detail, introduced sustainable supply chains as a concept, and highlighted their importance. But how can sustainability be driven through supply chains? This year, a group of LBS students came together to explore this topic in more detail (read more about us in our first post). We have brought together the insights gleaned from our networks, the LBS student and alumni community, and the guidance of faculty and staff in a series of posts that we hope can drive further conversation. Here, we share the outputs of our research and interviews in the hopes that you find it interesting and useful. In this post, we introduce how the impact of sustainable supply chains can be measured.

What you measure is what you get.

To take appropriate action and set meaningful goals towards sustainability, companies must first understand their current situation and identify means to measure the impacts of their efforts. However, in a survey by The Sustainability Consortium[2], less than one fifth of the 1,700 firms surveyed said that they had a comprehensive view of their supply chain impact and more than half were unable to identify issues in their supply chain.[3] This lack of understanding prohibits further organizational progress as companies are unable to appropriately identify issues to address and support proactive, long-term, data-based decisions.

What are the paths to systematic measurement?

Different methods exist to assess the environmental and social impacts of a company’s supply chain. The following are examples of measurements that can be used together or selectively to capture the most relevant information depending on the nature of operations and the industry:[4]

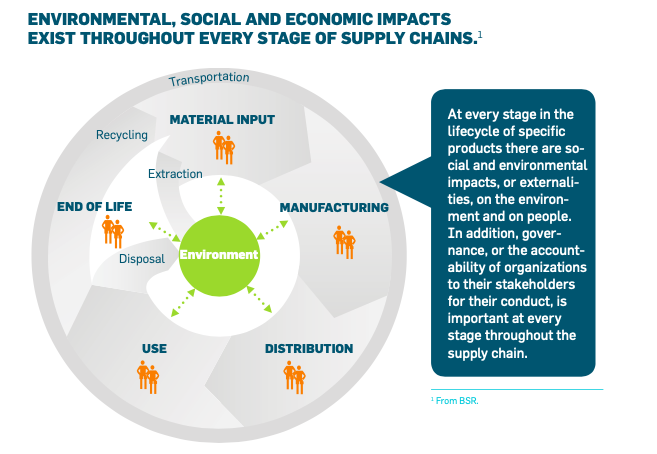

Life cycle assessment (LCA): The LCA quantitatively compiles and evaluates the inputs, outputs, and the potential environmental impacts of a “product system”9, which refers to the entire life cycle of a product, from extraction of natural resources to final waste management of the disposed product (“cradle to grave”). As an example, to measure the impact of a car, we would need to measure the emissions during its useful life but also the impact of the components, maintenance, the roads required, and finally how materials are handled at the end of its life. In the case of electric vehicles, to understand if they are more environmentally friendly, we would need to consider the impact of battery creation, usage, and disposal and the source of energy used to charge them.

Carbon footprint: Carbon emissions are the most widely used sustainability measure, mainly because of associated regulations and public awareness of climate change. Carbon footprints can be measured at an organisation level (e.g. building energy use), at a value chain level (e.g. emissions from clients, suppliers, and end of life emissions), and at a product level (included in the LCA). Emissions are categorised in three scopes depending on their proximity to core business operations: Scope 1 – includes direct emissions, Scope 2 – emissions from purchased energy, and Scope 3 – other indirect emissions.[5] It is estimated that, on average, 74% of an industry’s carbon footprint is attributed to upstream Scope 3 emissions. This highlights the criticality of measuring GHG emissions along the entire supply chain in order to drive real change and identify greater cost reduction opportunities. This was the case for Walmart, deciding early on to track all three emission scopes in 2005. They are now engaged in a large-scale emission reduction plan, “Project Gigaton”, aligned with guidance of the Paris Climate agreement. By pushing suppliers to set goals and take actions, they plan to reach an emission reduction equivalent to 211M vehicles yearly between 2015 and 2030.[6]

Water footprint: Water footprints measure how much freshwater is used by a product or a consumption pattern. This includes the volume of water extracted from the ground minus what is returned to the system, the volume of rainwater consumed, and the volume of freshwater pollution. The food and beverage and textiles industries are known to have some of the largest supply chain water footprints, although the textile footprint is often not measured. In general, the data and benchmarks for identifying product water usage is difficult to obtain or potentially unreliable.[7] However, some companies are setting the example. Levi’s “Water<Less” strategy aims at both reducing the amount of water used for producing clothes and water pollution. By 2025, the firm will onboard 80% of its factories and fabric mills in the programme.

Sustainable non-renewable materials management: Over the last 30 years, global material consumption has increased by 80% in absolute terms and it is expected to be multiplied by 2.7 by 2050. Currently, the recycling of metals is essentially non-existent (less than 1%) while the use of these materials is increasing rapidly.[8] To enable continued growth, it is therefore important to carefully analyse the supply of non-renewable materials. To do so, companies must be aware of the criticality of each material they use, like a metal, by considering the stock available, depletion rate, potential for a substitute, recycling options, and level of information available about mining methods.

Social impact[9]: There is no simple and clear measure of the social impact of supply chains. However, companies have the responsibility to ensure they follow basic principles of human rights and labour practices throughout their supply chain. This may include ensuring no forced work or child labour is used or that human rights abuses are not occurring. The UN Global Compact guide for sustainable supply chains recommends actions to ensure fair social practices, in addition to environmental and anti-corruption principles.

What are the challenges companies face?

- Defining the scope of supply chain operations

An initial decision that needs to be made in determining measurement methods is about the boundaries of an organisation. This can be exceedingly challenging for large companies where lower-tier suppliers often represent the highest risk given the multiple layers between them and limited resources available to monitor and disclose sustainability information. Companies need to decide the limits of the operations that they will measure, and what they will take responsibility for. Balancing limit definitions with what they are able to control with reputational risk associated with having unmonitored suppliers is an ongoing challenge. With scope in mind, companies need to establish long-term sustainability goals, require first-tier suppliers to set their own supporting targets, and include lower-tier suppliers in the broader sustainability strategy.[10]

- Making sense of sustainability information

The interpretation of data obtained from measurement presents its own sets of challenges. Consolidating the results, dealing with variability and uncertainty, and translating the information into managerial decisions are not easy tasks. Just as with financial data, companies have the ability to interpret and present sustainability information related to their supply chain’s impact. Given the lack of widely accepted auditing or legal frameworks and the novelty of measurement standards, the impetus is on companies to set the example for good reporting practices.[11]

The Network for Business Sustainability offers a useful framework to help supply chain and sustainability leaders jumpstart this process by identifying the motivators, levers, and baseline practices that develop competitive and sustainable global supply chains.

Want to know more about sustainable supply chains?

We hope this introduction to sustainable supply chains piqued your curiosity on the topic and spurred interest in potential methods to make change. In our next posts, we will discuss the latest trends in supply chain sustainability and help you understand how you can promote sustainability from within your organisation, no matter your role. We would love to hear your thoughts on the topic or learn from any experiences you have in supply chain sustainability, so do not hesitate to connect with us!

[1] Chorn B., Sisco C., Pruzan-Jorgensen P. M., 2015. Supply Chain Sustainability: A practical guide for continuous improvement. Available at: https://d306pr3pise04h.cloudfront.net/docs/issues_doc%2Fsupply_chain%2FSupplyChainRep_spread.pdf

[2] A nonprofit organization dedicated to improving the sustainability of consumer products, link to their guide here

[3] McKinsey. 2016. “Starting at the source: Sustainability in supply chains”. Accessed 03/07/2020. Available at: https://www.mckinsey.com/business-functions/sustainability/our-insights/starting-at-the-source-sustainability-in-supply-chains

[4] Bouchery, Y., Corbett, C., Fransoo, J. and Tan, T., 2016. Sustainable Supply Chains. New York: Springer

[5] Bouchery, Y., Corbett, C., Fransoo, J. and Tan, T., 2016. Sustainable Supply Chains. New York: Springer

[6] Walmart Global Responsibility Report 2018. Available at: https://corporate.walmart.com/media-library/document/2018-global-responsibility-report/_proxyDocument?id=00000170-ac54-d808-a9f1-ac7e9d160000

[7] Bouchery, Y., Corbett, C., Fransoo, J. and Tan, T., 2016. Sustainable Supply Chains. New York: Springer

[8] Bouchery, Y., Corbett, C., Fransoo, J. and Tan, T., 2016. Sustainable Supply Chains. New York: Springer

[9] Chorn B., Sisco C., Pruzan-Jorgensen P. M., 2015.

[10] Villena V., Gioia D., 2020. « A more sustainable supply chain ». Accessed 03/07/2020. Available at: https://hbr.org/2020/03/a-more-sustainable-supply-chain

[11] Bouchery, Y., Corbett, C., Fransoo, J. and Tan, T., 2016.

The Wheeler Institute is seeking to understand, illuminate and offer solutions to the challenges faced by the developing world, with an aim to identify the role of business in addressing these challenges and a focus on the implications and actions for those in developing countries. In support of our students, we approach this blog section as a reflective platform and a space where individuals can generate debate as long term agents of positive change.

The Sustainable Supply Chain Cohort was an initiative of the Student-led Learning team which creates experiential learning opportunities through student leadership, in addition to their other initiatives such as the Student Leadership Incubator and Project Aasha. Contact the Student-led Learning team for more information about student leadership roles within the LBS community.